The Italian building culture is based on bricks and stones for the walls, but until the first half of the 20th century almost all the floorings and the roof structures were made of timber, often richly decorated with paints or bas-reliefs. In general, the conservation authorities recommend that these structures should be maintained as integrally as possible, even when structural upgrading is needed, and in effect the interventions with glued-in rods or other analogous techniques is an interesting alternative to the replacement of whole timber elements. Adding reinforcing materials to the existing timber is therefore a quick, cheap and well established practice, but two important issues need to be further developed: the compatibility between the involved materials and the reversibility of the intervention.

A large effort for the development of improved adhesive-based systems has taken place in Italy over the last 5 years, both in research institutions and in the industry. Among the various initiatives, a highly significant one has been the 3-years "Parnaso" project having the aim of the development of consolidation systems of old timber structures highly compatible with wood and as much reversible as possible.

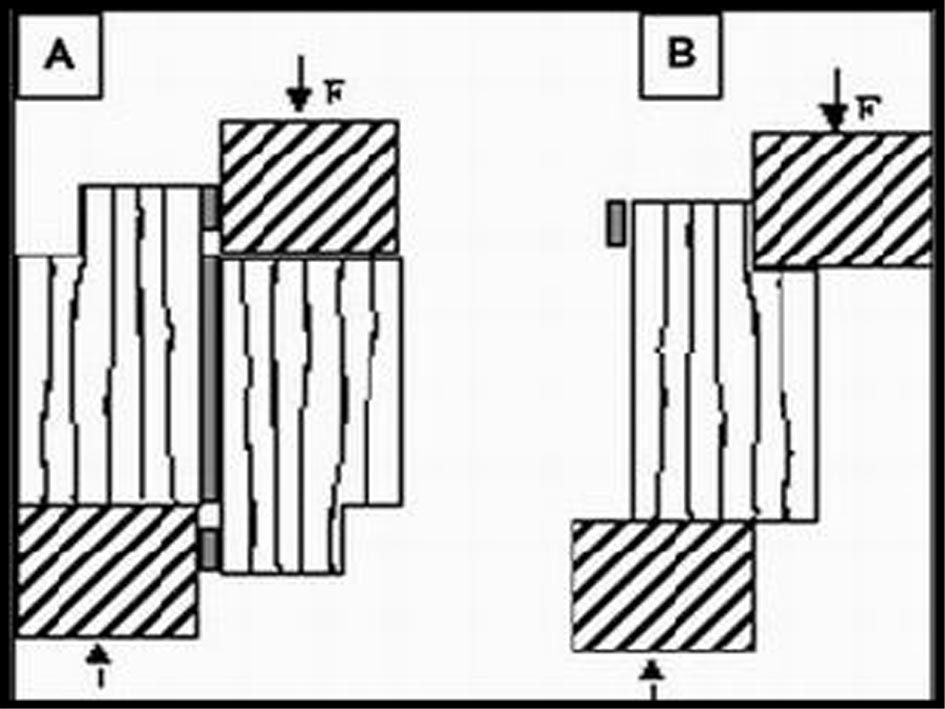

In order to obtain an adhesive highly compatible with wood it is necessary to point out a specific test taking in account the two main factors characterising the on-site bonding of timber: a thick glueline of the joint and the application of the adhesive without pressure. A new geometry for the shear test specimens was then developed in such a way that a direct comparison is possible between the shear strength of the bondline and the actual shear strength of wood, both measured on the same specimen (fig. 1). In fact each specimen is tested twice in shear:

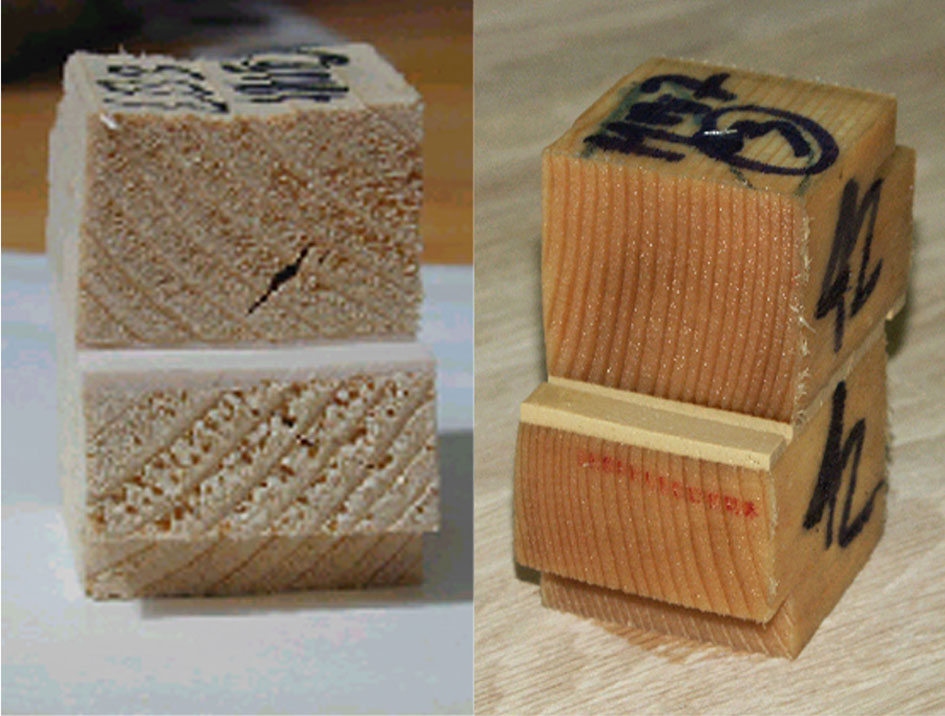

o the first loading step is at the wood-adhesive interface (fig. 1a), with an offset equal to the adhesive's thickness (3 mm in our case), both in standard and completely wet conditions after some accelerated ageing cycles (fig. 2);

o the second loading step is performed on solid wood, on one of the two adherends, without any offset (fig. 1b), both in standard and completely wet conditions after the same accelerated ageing cycles.

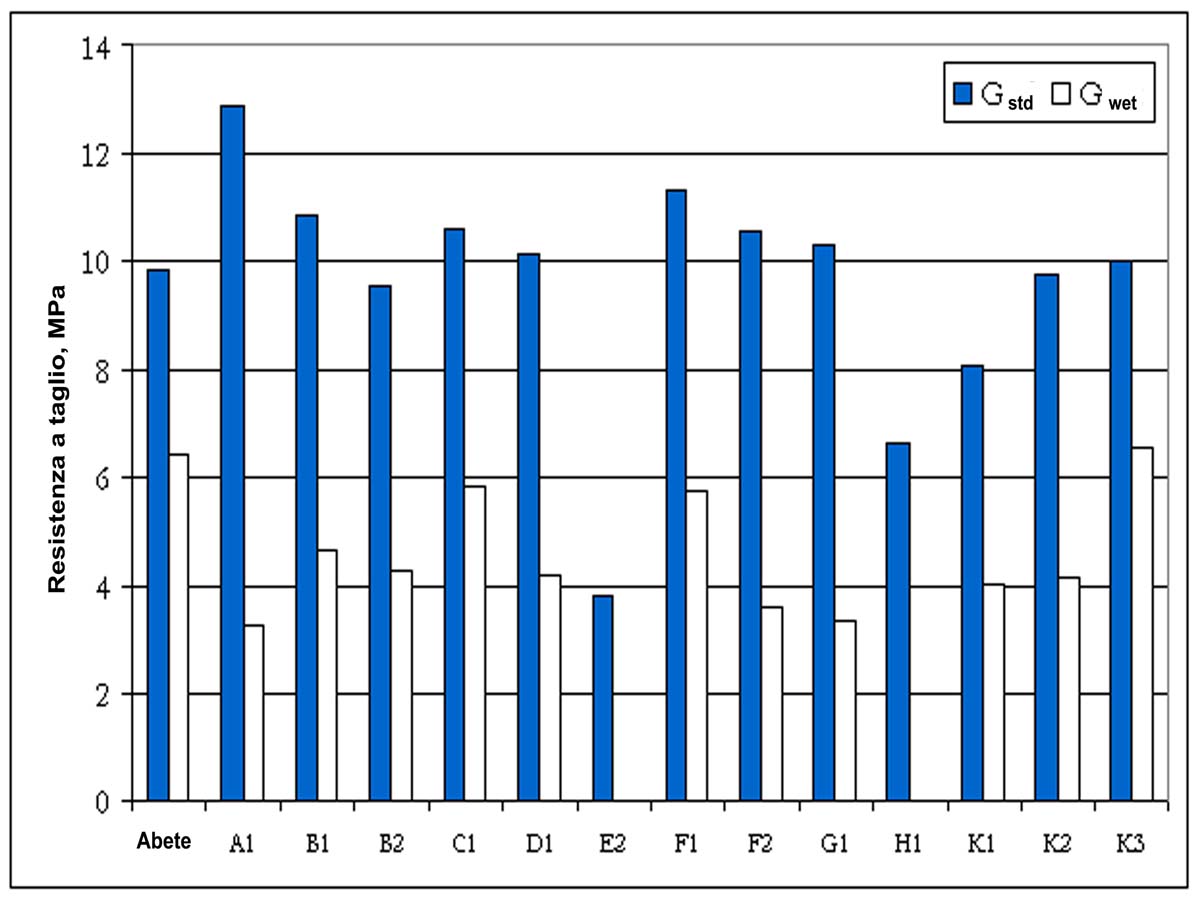

By this approach a mechanical compatibility coefficient can be calculated based on the real values of shear strengths as related to the same wood batch used for the glue. The methodology has been therefore applied both to commercial and experimental products (fig. 3), thus demonstrating that the majority of the adhesives actually commercialised for structural wood repair are non suitable for such application, whereas a set of new specific products has been developed. Moreover a classification of adhesives could be proposed that is referred to numerical values and then to impartial evaluations. The new adhesives set up during the Project have been applied on some real experimental yards (figg. 4-14).

In addition, the Life Cycle Assessment (LCA) of the most used techniques has showed that a rational use of adhesives has a smaller environmental impact than the substitution of the whole beam.

Immagini: