In Europe per annum more than 80 million cubic meters of sawn timber are dried in industrial kilns. This drying process consumes huge amounts of energy but is an unavoidable production step in the woodworking industry and a pre-condition for high-value application.

Science related to wood drying and thermal treatment has a long history in Europe. Fundamental work during the last century and the technical developments in electronics and process control during the last 40 years have contributed to the transformation of the timber drying process from an empirical skill to a controlled industrial operation. Nevertheless there is an enormous field of problems and questions in the science of timber drying and thermal treatment, which still have to be solved in order to improve and optimise theses important industrial processes. During drying, sawn timber is exposed to high risks which can affect the integrity and quality of the material by generating internal damage coming from the stress induced by the physics of the process itself and the quality of drying has a strong effect on the behaviour of wood during the end use phase.

Drying causes a non uniform reduction of the moisture content through the section of wood, since the outer regions get dry before the inner core of the material, this inducing plastic strain and subsequent damage. Since now, in order to quantify and control the internal stress and subsequent strain of wood, only destructive tests at the end of the drying process were possible. They provide information about the quality of the dried wood but -being end-process measurement- they not allow to control it.

A technical challenge is therefore the development of reliable sensors fit for measurement of the quality state of wood during drying in order to allow the computer to control and mange the process This innovative system needs to be low cost, easy to use, non destructive and minimize the interference of the measurement specimen with the material. Moreover, it has to be chemically inert towards the environment of the drying kiln.

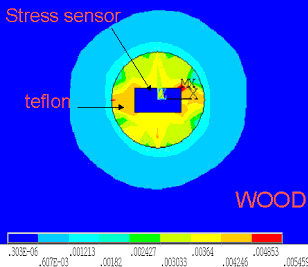

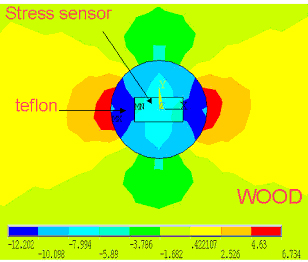

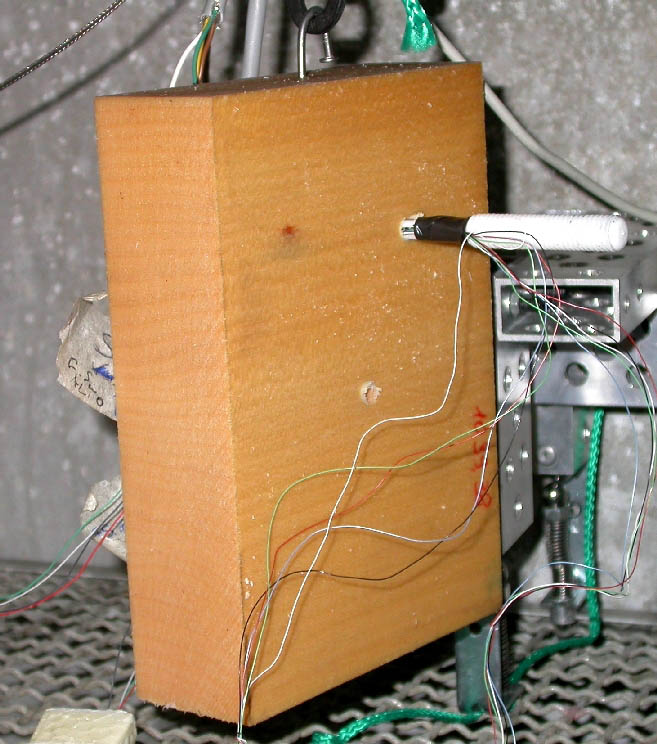

To address these needs a custom sensor, easy to use was designed, based on a silicon micro machined pressure gauge inserted in a Teflon nail. Teflon provides protection and works as a medium between the gage and wood, and it makes it possible to handle the sensor.

The influence of the Teflon package on the gauge sensitivity was studied by finite element simulation and compared with measurements of internal stress during drying tests on different wooden species at different drying conditions.

The results show the effectiveness of the system and a good correlation with the quality of the dried products.

The research project, carried out with the financial support of the Autonomous Province of Trento is still in progress. Different versions of the sensor have been carried out and tested in laboratory conditions and the next step will be to test the sensor in industrial conditions with the aim to develop a working prototype and the related model for the control of the process based on the data coming from the sensor.

Immagini: