The development of innovative chemical processes, with high performances and low environmental impact, is crucial for a sustainable growth. In this perspective membrane technology can offer important new opportunities in the design, rationalization and optimization of processes and products.

In particular, catalytic membrane reactors are an interesting example of integrated system in which molecular separation and chemical conversions are combined in one step

One of the main advantages of the membrane reactors, in comparison to traditional reactors, is the easy recycling of the catalyst. Moreover, the selective transport properties of the membranes can be used to circumvent the equilibrium limitation, to selectively remove products from the reaction mixture in order to prevent consecutive reactions and for the selective supply of reagent.

The application of catalytic membrane reactors appears of particular interest in several areas such as: hydrogen production, oxidation reactions and enantiomeric productions.

Catalytic membrane reactors offer interesting opportunities for the hydrogen production, up-grading and purification. In the catalytic membrane reactors, the selective removal of hydrogen increases the conversion. Steam refoming and the partial oxidation of methane (for the hydrogen production), the water gas shift for consequent up-grading) and the selective oxidation of the CO (for the purification of the H2) are the main reactions studied in this field at the Institute on Membrane Technology (ITM-CNR).

A promising research activity for the heterogenization of catalysts into polymeric membrane is also in progress.

In this work oxidation reaction of specific interest such as the stereoselective sulfoxidation of alkyl-aryl sulfide and the oxidation of secondary amines catalyzed by a Ti (IV) catalyst bearing C3-symmetric trialkanolamine ligands, have been investigated.

Novel heterogeneous catalysts, highly stable and recyclable, have been synthesized by incorporation of this catalyst in polymeric membranes.

Polyoxotungstates, anionic cluster of W and oxygen with interesting properties as photocatalysts, have been also heterogenized in polymeric membranes to carry out oxidation reactions of organic substrates in water and wastewater treatment.

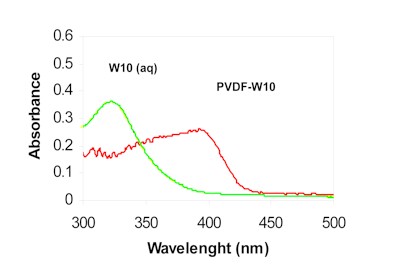

One of the most interesting observation emerging from the investigation of these photocatalyc membranes has been the shift of the charge transfer (CT) band of the decatungstate (W10O324-) heterogenized in polyvinilidene fluoride membrane (PVDF-W10), in comparison to homogeneous catalyst (figure 1). This shift of the CT band is very interesting for the development of sustainable processes using solar radiation for catalyst activation.

Membrane reactors using biological catalysts can also be used in production processes. At the ITM methodologies for the preparation of emulsions (sub-micron) oil in water have been developed and such emulsions have been used for kinetic resolutions in heterogeneous systems catalyzed by enantioselective enzyme.

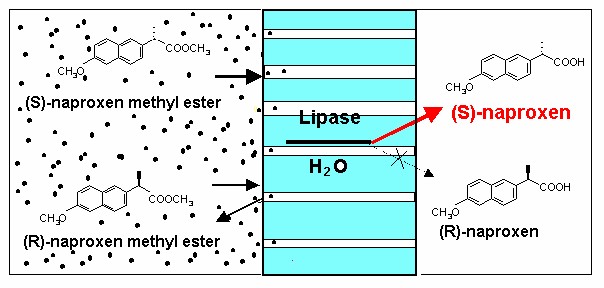

A catalytic reactor containing membrane immobilized lipase has been realised. In this reactor the substrate has been fed as emulsion. The distribution of the water organic interface at the level of the immobilized enzyme has remarkably improved the property of transport, kinetic and selectivity of the immobilized biocatalyst (figure 2).

Immagini: