The growing interest for appropriate formulations of final products in various industrial areas, from pharmaceutical to cosmetics, agro-foods, biotechnology, fuels, etc., attracted attention to the possibility of producing stable monodispersed emulsions using microporous membranes, realising the so-called membrane emulsifier. Advantages of this methodology are: lower energy cost; no mechanical stress for the treated solutions; mild operating conditions, better control of droplets size, etc.

This approach has been already realised in producing oil-in-water as well as water-in-oil emulsions. Interesting apparently linear relationship between droplets diameter and nominal membrane pore diameter has been also observed for particles in the range of 5 ¡V 20 micron.

However, in the previous studies mainly ceramic microfiltration membranes have been used obtaining emulsions with droplets size of the order of few microns (3 ¡V 10 micron).

A significant interest exists for producing sub-micron emulsions with droplets of the order of 0.1 ¡V 1 micron and lower if possible (e.g. microemulsions with droplet size lower than 50 micron).

Using a new approach based on ultrafiltration and nanofiltration membranes, stable and uniformly dispersed oil-in-water emulsions with droplets size of the order of 0.1 ¡V 1 ?Ým have been prepared (Fig 1).

These results are possible when an appropriate pretreatment of the hydrophilic membranes is carried out which permits the diffusion of the organic phase in the polymeric membrane phase. The pre-treatment consisted in removing the polar internal liquid phase (water) and substituting it with the apolar solvent. This was achieved by permeating through the membrane miscible solvents of gradually decreasing polarity, so that water was washed out and it was replaced with pure organic solvent.

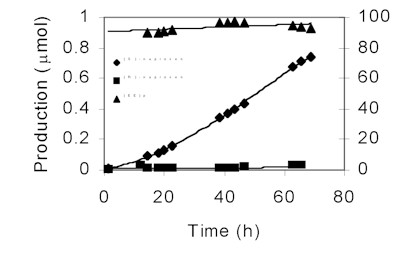

The potentiality of these systems have been already confirmed in the production of significantly high enantiomeric excess of the (S)-naproxen acid (anti-inflammatory drug) from racemic mixtures of (R, S)-naproxen methyl ester in emulsion enzyme membrane reactors (Fig. 2). These results have been related to the improvements of the mass transfer efficiency in the emulsion enzyme membrane reactor realized, where the practically monodispersed emulsion well reproduced the organic/water interface within the membrane pores. In these conditions, the pores worked as continuous micro tank reactors where the immobilized lipase could be activated by the organic/water interface so that enzyme stability as well as activity and enantioselectivity were preserved.

The same methodology might be utilised in the preparation of stable microemulsions of oils for combustion processes, in drugs formulations, cosmetics, liquid crystals, and in general in a large variety of significant cases.

L. Giorno, L. Na, E. Drioli, Preparation of oil-in-water emulsions using polyamide 10kDa hollow fibre membrane, J. Membr. Sci., accepted.

Immagini: