The ultra-high temperature ceramics (UHTCs) draw the interest of the materials engineering to designe thermal protection structures and control surfaces for the sharp leading edge technology. Sharp leading edges for reentry vehicles or hypersonic space-crafts are two leading examples. Thhank to this new concept, improved flight performances together with enhanced safety for the crew, larger cross-range, wider launch windows, and safer landing for aborted flight plans can be achieved.

Ceramic composites based on transition metal diborides MB2 (M=Zr,Hf) combine thermal stability at high temperatures together with an outstanding ability to effectively transfer heat, making them currently among the most studied systems.

The oxidation resistance of pure MB2 is lacking for the intended applications, so that appropriate refinements of the basic compositions must be necessarily addressed to fit the expected requirements.

Although some UHTCs demonstrated room temperature flexure strength up to 1GPa, a lack of damage tolerance typical of brittle ceramics still needs to be fixed. The development of tougher and oxidation resistant massive UHTC can be pursued through the achievement of a "composite inside a composite". Such a multi-scale architecture may provide damage tolerant and strong structural ceramics.

ISTEC collaborates in R&D research programs led by ASI, ESA, CIRA, Thales-Alenia Space, C.G.Space, Ministry of Defense. Mmore recently CNR-ISTEC is involved in an international Joint Project between CNR of Italy and the National Science Foundation of US.

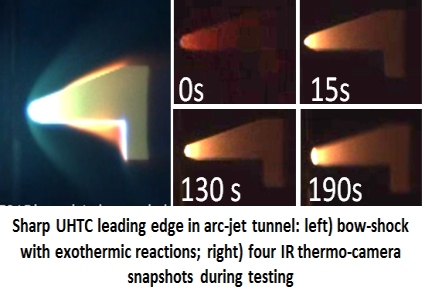

Immagini: