Those research activities consist of an innovating experimental work on

the so called "Smart Materials". These materials act in particular ways

and times when some specific kind of thermo-mechanical conditions are

applied. When removing those conditions the entire system will recover

its original status.

Particular active materials are shape memory alloys (SMA) made by

Aluminium Copper and Nickel, or by Nickel and Titanium, whose commercial

name is Nitinol. SMA are commonly used as stand-alone structures or as

reinforcing materials in composite structures so to make Smart Materials.

The most common use of SMA has been found in polymers matrix applications

where they work as actuator of the entire composite structure or as

sensors.

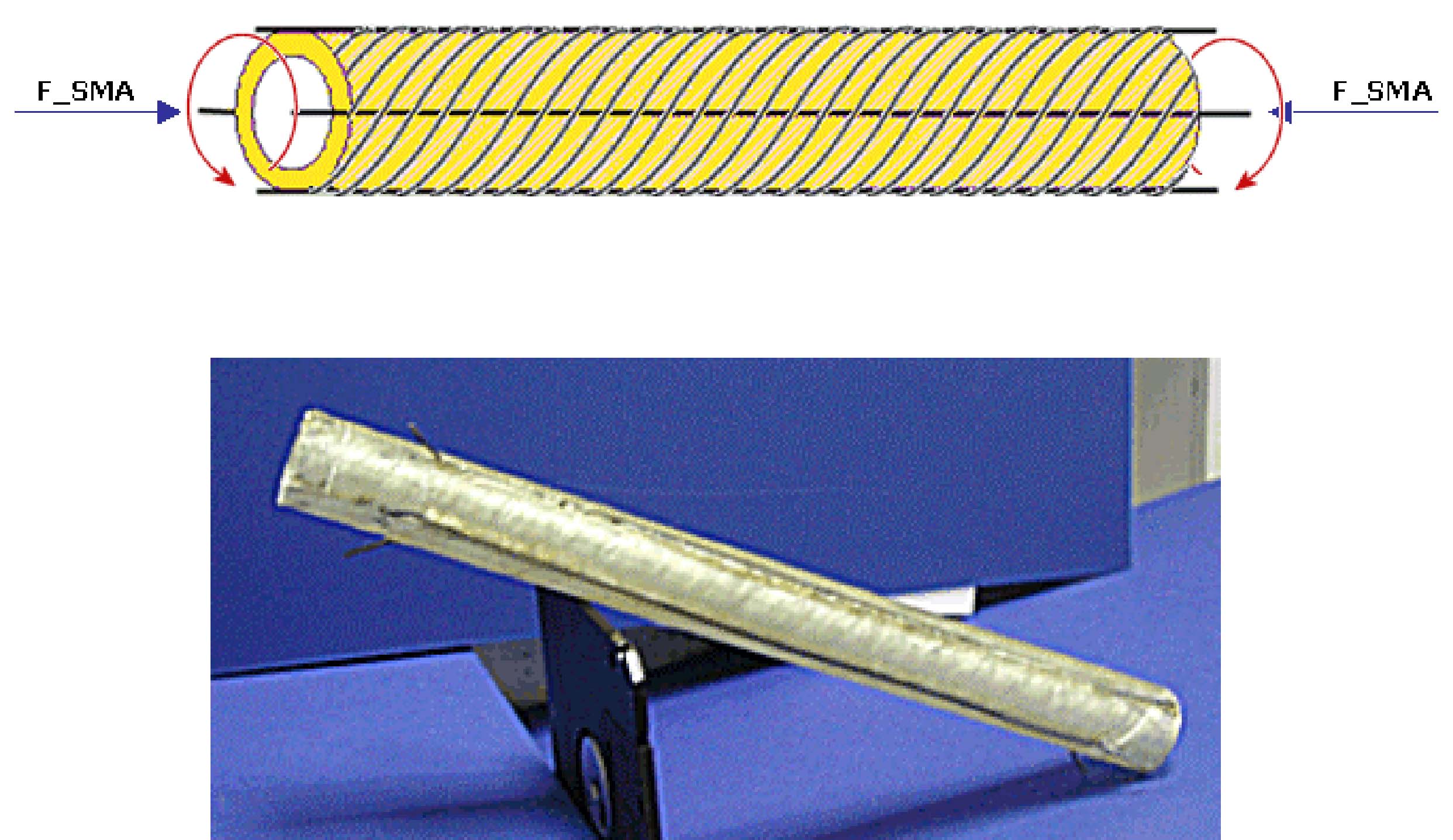

The main purpose of these activities was to design and build a particular

actuation system, that consists in a glass fibers (width: 3mm) in epoxy

matrix tube, with embedded four Nitinol wires (length: 200 mm, internal

diameter: 20 mm, maximum thickness: 2 mm). The tube was realized by using

the filament winding technology, with a winding angle of 60°. Those wires

were put along the longitudinal axis of the tube. By heating the SMA

wires over a characteristic temperature, its internal structure changes

showing a macroscopic contraction of the same wires. This process means

an application of a compression stress on the tube so to let it torque

thanks to its anisotropic structure. The particular geometry was the

result of a mathematical modelling. During the testing of that system,

while the Nitinol wires were heated by electricity, the tube showed a

torsion of 4.5°± 0.1°. When removing the electrical power, the entire

system recovers its original status.

This kind of actuator has been supposed as a substitute of the

mechanical and hydraulic systems which are built on airplanes to move the

mobile surfaces on the wings.

The entire work has been brought up by the collaboration of I.M.C.B.

(Composite and Biomedical Materials Institute) C.N.R with C.I.R.A.

(Italian Center of Aerospace Research and D.I.M.P. (Materials and

Production Engineering Department) of the University "Federico II" in

Naples.

During the study of that project many suggestions were proposed

to improve the device design and to increase its functionality. Actually

particular thermo-mechanical processes and better temperature control

systems for the SMA wires are being experimented at the I.M.C.B. to get

more information about the behavior of the shape memory alloys.

Immagini: